Basic process of battery cabinet production

Welcome to our dedicated page for Basic process of battery cabinet production! Here, we have carefully selected a range of videos and relevant information about Basic process of battery cabinet production, tailored to meet your interests and needs. Our services include high-quality Basic process of battery cabinet production-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Basic process of battery cabinet production, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

The Battery Manufacturing Process

Discover the battery manufacturing process in gigafactories. Explore the key phases of production – from active material to validation, as

The Manufacturing Process of Lithium Batteries

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in

Battery cabinets are process materials

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

Energy storage battery cabinet production process

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

Illustrated explanation of the battery cabinet production process

Battery formation (BF) - a critical step in the battery production process > Essential stage every battery needs to undergo in the manufacturing process to become a functional unit > Activation

Battery cabinet production process English

The production of lithium battery modules, also known as Battery Packs, involves a meticulous and multi-step manufacturing process. This article outlines the key points of the lithium battery

Battery Pack Manufacturing Process

In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and future innovations.

How AZE Systems Manufactures BESS Battery Energy Storage

Manufacturing a BESS cabinet requires a combination of advanced engineering, precise manufacturing, and rigorous testing. By following the steps outlined above, you can

Battery Manufacturing Basics from CATL''s Cell

A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

FAQs 6

What is the battery manufacturing process?

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from material selection to the final product’s assembly and testing.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

How is automation used in battery manufacturing?

As a result, automation is used to integrate complex sub-processes into a unified manufacturing process. The process consists of three phases: electrode manufacturing, cell assembly, and forming, aging, and validation. The initial step in battery manufacturing is the production of two covered layers, the anode and the cathode, called electrodes.

What is the first step in the lithium battery manufacturing process?

Electrode manufacturing is the first step in the lithium battery manufacturing process. It involves mixing electrode materials, coating the slurry onto current collectors, drying the coated foils, calendaring the electrodes, and further drying and cutting the electrodes. What is cell assembly in the lithium battery manufacturing process?

How is a battery made?

The initial step in battery manufacturing is the production of two covered layers, the anode and the cathode, called electrodes. The process uses two identical and separate production lines, one for the anode and another for the cathode, to prevent cross-contamination. Typically, the anode consists of a copper foil coated with graphite.

What is the final stage in the battery manufacturing process?

The final stage in the battery manufacturing process is forming, aging, and validation. Conditioning is a critical stage in the process, where the cell is charged, discharged, and tested to evaluate its characteristics and performance.

Related links

- Battery cabinet production operation process

- New Energy Battery Cabinet Discharge Process

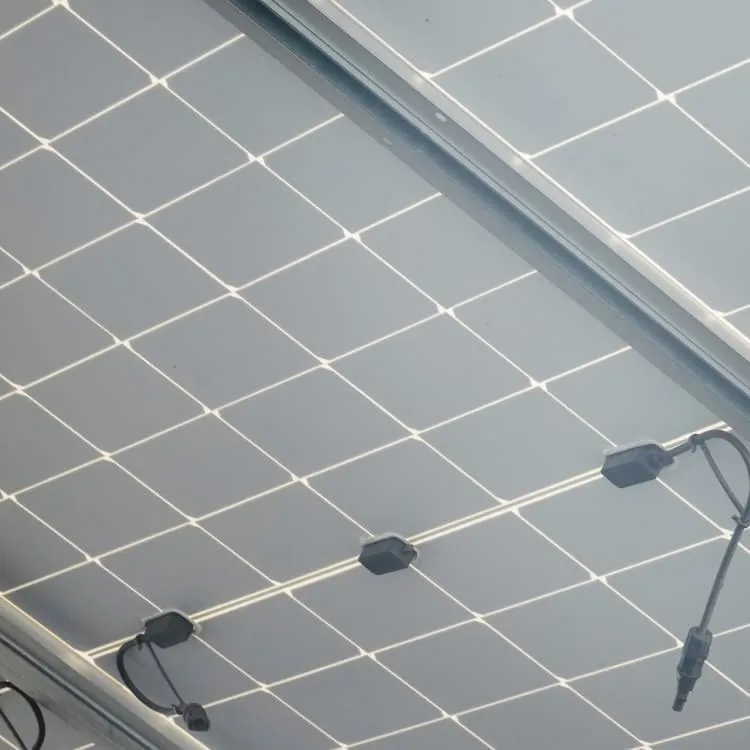

- Photovoltaic energy storage cabinet production process base station

- The whole process of small battery cabinet installation site

- Battery cabinet base station energy heat shrink production

- Battery station cabinet production equipment

- Lithium battery station cabinet automation production price

- Battery cabinet assembly production integrated system

- Energy storage cabinet battery production in El Salvador

- South Ossetia production battery cabinet supplier