What equipment is used for pack lithium batteries

Welcome to our dedicated page for What equipment is used for pack lithium batteries! Here, we have carefully selected a range of videos and relevant information about What equipment is used for pack lithium batteries, tailored to meet your interests and needs. Our services include high-quality What equipment is used for pack lithium batteries-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

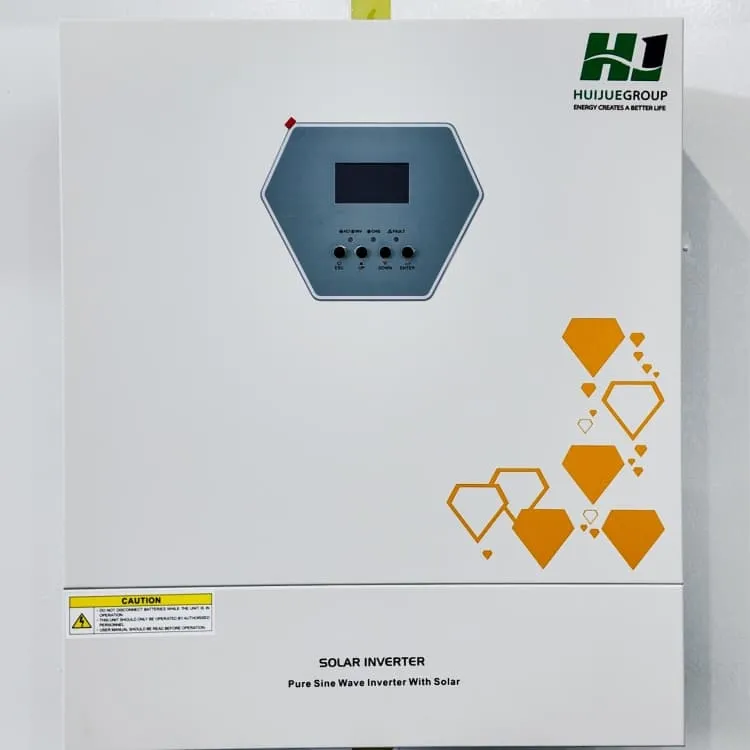

Wherever you are, we're here to provide you with reliable content and services related to What equipment is used for pack lithium batteries, including cutting-edge home energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Battery Production | Lithium-ion & EV Battery Manufacturing

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

What Is a Lithium Battery Pack Production Line?

Lithium battery packs are essential for: Electric Vehicles (EVs): Powering cars, bikes, and scooters. Energy Storage Systems (ESS):

Battery Manufacturing Basics from CATL''s Cell

Equipment plays a critical role in determining the performance and cost of lithium-ion batteries. Mirroring the three manufacturing stages,

What Packaging Should I Use to Ship Lithium-Ion Batteries

What Packaging Should I Use to Ship Lithium-Ion Batteries. When shipping lithium ion batteries there are several rules and regulations to consider - dangerous goods classifications

Preventing Fire and/or Explosion Injury from Small and

Introduction Small and wearable electronic devices used in workplaces (e.g., body cameras) rely on a power source that stores a high amount of energy in a small space (i.e., high energy

Li-ion cell manufacturing: A look at processes and

The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

A Complete Guide to Lithium Battery Transportation

Understand 2025 lithium battery transportation rules, including packaging, labeling, and compliance to ensure safe and legal shipping across all modes.

Introduction to Production Equipment and Testing Methods for

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Production Process of Lithium Battery Pack Cells

The lithium battery pack production equipment used in the first stage mainly includes a vacuum mixer, coating machine, roller press, etc.; the middle process mainly

Lithium-Ion Battery Assembly Process & Key Stages Explained

Explore a step-by-step guide on lithium battery pack assembly and cell making equipment.

FOREWORD

This Battery Information Factsheet (BIF) is intended to provide information for the safe handling, storage and transport of lithium batteries by professionals. It offers Good Practice Guidance

Lithium Battery PACK Production Line Processes and

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Introduction to Production Equipment and Testing Methods for Lithium

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Custom Battery packs for Medical Equipment

Smart Power for Medical Equipment For over 35 years, Excell Battery has been a leading OEM supplier of smart battery solutions for advanced applications, including critical Class I, Class II,

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

The Manufacturing Process of Lithium Batteries

The lithium battery manufacturing industry is dominated by countries like China, Japan, and South Korea, which are major manufacturers and suppliers of

How to safely pack and ship batteries

Regulations difer depending upon what type of lithium battery you are shipping (lithium ion or lithium metal) and whether you are shipping batteries packed with equipment or batteries

Battery Guidance Document

Lithium-ion batteries (also abbreviated as Li-ion batteries) are secondary (rechargeable) battery where the lithium is only present in an ionic form in the electrolyte. Also included within the

Ultimate Guide to Equipment for Lithium Battery Assembly: Types

From electrode coating machines to pack assembly lines, each piece of equipment plays a vital role in ensuring efficiency, safety, and quality. Advanced machinery offers

Lithium Battery PACK Production Line Processes and Equipment

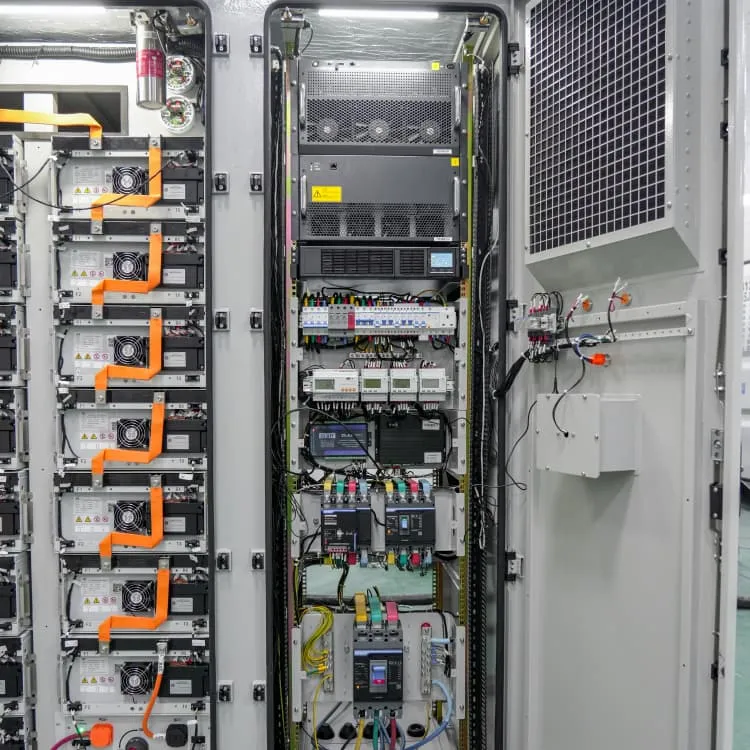

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser

Battery Cell, Module, and Pack Cycler Test

Battery Cyclers and Simulation. Precision charge/discharge, simulators, and electrical safety test equipment for lithium ion battery and ESS.

Li-Ion Prismatics

Use of Lithium Ion Batteries and the Design of Equipment That Uses These Batteries In general, lithium ion batteries are used in battery packs that contain both lithium ion batteries and

Guide to Shipping Lithium Batteries

Safely ship lithium batteries with this guide. Discover packaging instructions, shipping labels, and restrictions to ensure compliance and

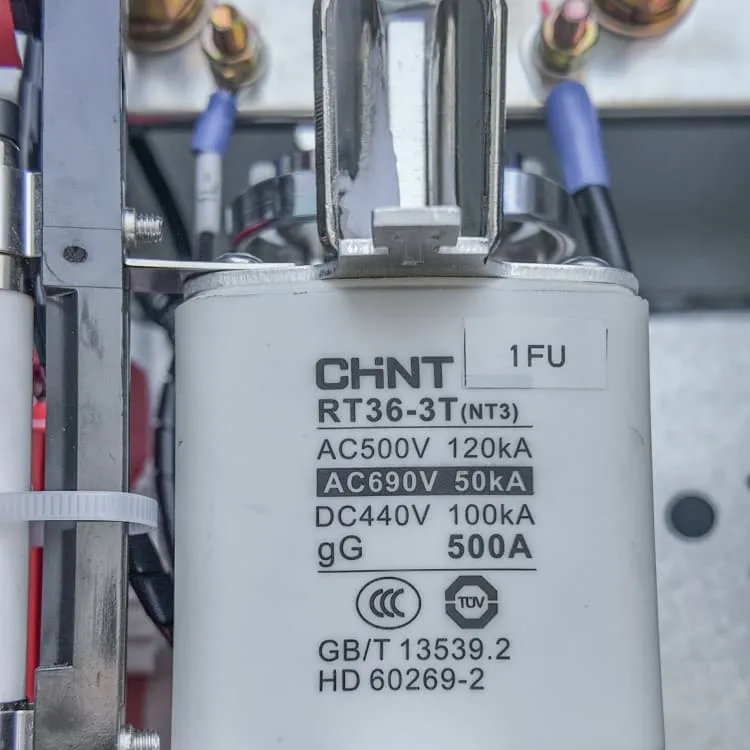

Lithium Battery Pack Introduction to Common Equipment during

The production process of lithium battery pack involves many equipments, including mixing equipment, coating equipment, winding equipment, hot pressing equipment,

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Lithium-Ion Battery Assembly Process & Key Stages

Explore a step-by-step guide on lithium battery pack assembly and cell making equipment.

How lithium-ion batteries are manufactured

Stacking machines are used for pouch and prismatic cells. Winding machines create cylindrical jelly-rolls under tight control. Tabs are welded to current collectors via laser welding.

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Packing and Shipping Batteries: A Guide | How to Ship

Types of Batteries There are several types of batteries commonly used, including lithium-ion, alkaline, nickel-cadmium, nickel-metal hydride, and lead-acid. Each type of battery has its own

What Is a Lithium Battery Pack Production Line?

Lithium battery packs are essential for: Electric Vehicles (EVs): Powering cars, bikes, and scooters. Energy Storage Systems (ESS): Supporting renewable energy sources

FAQs 6

What is a lithium battery pack?

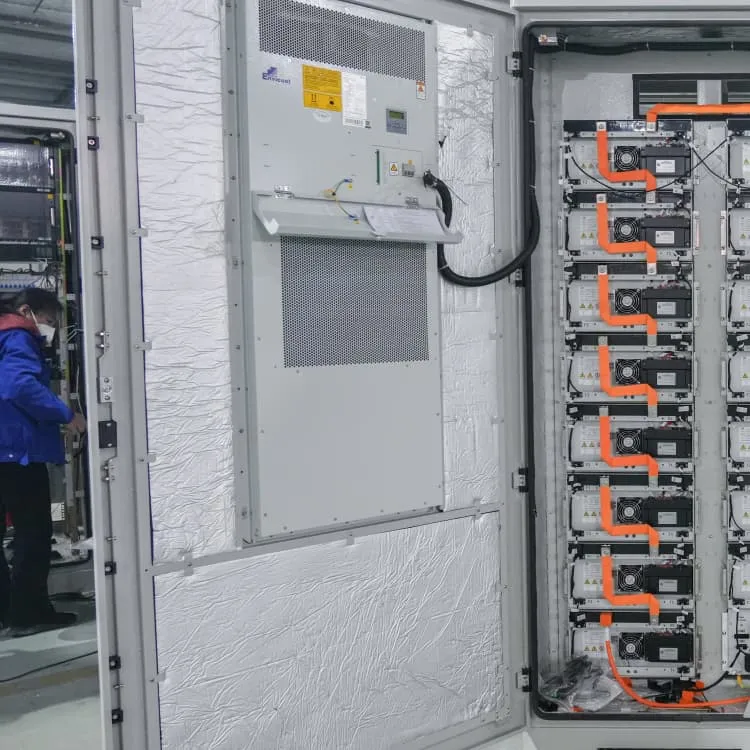

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

What do we have for lithium-ion battery pack assembly?

For lithium-ion battery pack assembly, we offer complete solutions. This includes different sizes of barley paper, battery cells, plastic holders, nickel strip, handheld spot welder, PVC, and high-temperature resistant adhesive tape. We also provide rolls of various widths and cut the length as per customer requirements.

How to contact lithium battery pack engineering team?

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

How does a lithium battery pack work?

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment. Quality Control: Every step, from mixing to testing, demands extreme precision. Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

What is the best packaging for lithium batteries?

Air Sea Containers offers UN approved Lithium Battery packaging suitable for the shipment of Lithium Ion and Lithium Metal Batteries via any mode of transport. Our best packaging for shipping lithium batteries is the 4DV Plywood Boxes, which are ideal for batteries over 12kg.

What are the components of a battery pack?

Busbars and Soft Connections: For electrical connections between cells. Protection Board: Includes the Battery Management System (BMS), responsible for battery protection and monitoring. Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices.

Related links

- What base stations use lithium iron phosphate batteries

- What batteries are used in Iraqi energy storage power stations

- What kind of batteries are used in Gabon s energy storage power station

- What are the lithium batteries for wind power generation systems

- What brand of batteries are used in energy storage stations

- What is pack lithium battery

- What is the price of lithium battery pack

- What size inverter can a 12V lithium battery be used with

- What is the most important thing about pack batteries

- What brand of lithium battery pack should I use